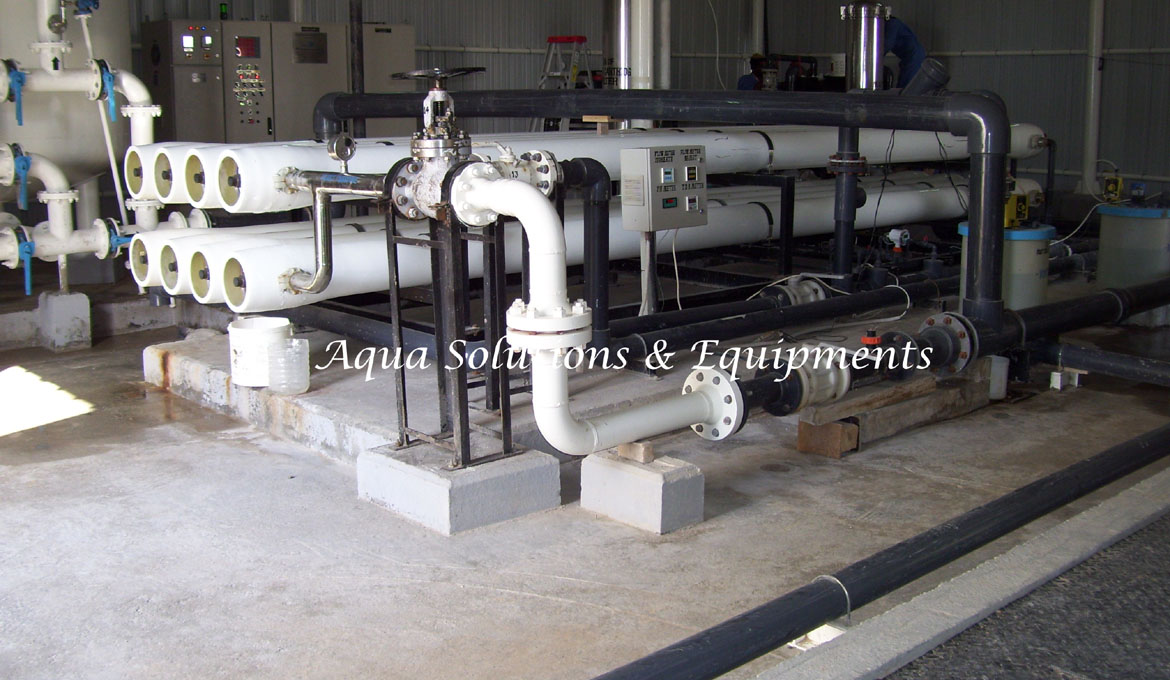

Commercial/Industrial RO System

Reverse Osmosis is gaining popularity day by day for treating raw water having high hardness, high TDS etc. for variety of applications including drinking, process use in industry, low TDS water for boiler, Pharmaceutical, Mineral water plants etc. RO plants are very user friendly, they do not require any chemical charging like Softeners & DM plants. Generally If the TDS of raw water is more than 500 PPM, RO plant becomes economical for capital as well as running cost. Off course, this needs to be worked out after carefully designing system.

Reverse osmosis (RO) technology is used in the water purification process to filter out dissolved solids and other large molecules. Typical applications of RO technology are seawater desalination, boiler feed water filtering, product rinsing, microelectronics production, laboratory testing, biotechnology, and other process that require highly purified water.

RO is currently considered one of the most economic and effective process for water desalination. Accordingly, it is often the appropriate technique to treat solutions having salt concentrations from 100 to over 50,000 mg/liter. Solutions with salinity from surface water to sea water, and even brines, can be treated by RO membrane.

Commercial RO System is mostly use in Restaurants, Hospitals, Schools, Malls and Hotels for supplying clean drink water. The industrial plant is best suited for small and largely industrials.

Our team of experts in Industrial RO systems works on below mentioned points at the site:

- Filtration

- Softening

- Distribution

- Ultra pure water

- Water reuse

- Disinfection

- Special processes

Benefits Of Industrial RO

Pre-treatment is a definite consideration when having an industrial RO system in place. This is the best way to ensure long system life and optimal performance, as well as minimise operating costs. Another important thing to consider is effective management; a consistent approach must be taken where the operation of the system and its maintenance is concerned.

A number of process factors will need to be monitored in order to come upon the right frequency of membrane cleaning and system disinfection. These include flow rates for concentrate and permeate. Knowing these figures will allow for the percent recovery rate to be calculated, which will ensure that membranes do not become prematurely fouled or scaled.

Industrial Reverse Osmosis systems are available in different capacities that are needed for various commercial and industrial purposes. These start at a minute 30 gallons per day to a whopping 500,000 gallons per day treatment capacity.

- Low maintenance cost

- Easy to use

- User-friendly system

- Fully automatic system

- Easy to install and service

- And more…